Work Experience (Copy)

My Work Experience

In the spring of 2018 I had the opportunity to co-op at Virtudent, a dental startup specializing in teledentistry. This was my first engineering job, and I was the sole engineer at Virtudent. My priority was to manage and repair and maintenance of portable dental kits, which at the time were prototypes and broke often. This often meant driving on-site when they broke and figuring out how to fix them as quickly as possible. The secondary task was to improve upon the kit, and over the course of my time there I researched and tested multiple additions and fixes to the kit. I worked closely with the COO and a team of dental hygienists to incorporate both patient and hygienist feedback into the overall design of the kit and communicated their input to an outside design firm. With the help of the design firm we were able to create a new model of the kit and start a manufacturing process before my co-op ended. This experience taught me how to problem solve in a fast-paced, high pressure job with no safety net to fall back on.

After my co-op at Virtudent, I realized that the most fun I had on co-op was when I was rapid-prototyping parts with the design firm. I added a minor in experience design to my degree, which examines how user experiences can shape the design of a product. I like this design minor combined with mechanical engineering because both programs teach you how to solve problems, but they approach these problems in completely different ways. I also joined Generate, Northeastern University’s student-led product development studio, and over the fall of 2018 I worked on a team of 7 to build a phone case with a wireless charging, modular battery pack that attached via magnets. This experience confirmed for me that I wanted to work in a product development field.

In the summer of 2019 I started my second co-op at Waters Corporation, which specialized in liquid chromatography and mass spectrometers. At this job I was one of hundreds of engineers working on a highly technical, fleshed out product, which totally contrasted my experience on my first co-op at Virtudent. While the pressure on me was much lower, I was able to learn much more from my coworkers and supervisors about some different technical aspects of mechanical engineering and product design. I honed my 3D CAD and drawing skills, spent time in a machine shop, and tried my hand at coding and electrical engineering design.

Now that I feel that I have a solid foundation in problem solving, design, and practical engineering skills, I want to pursue my dream of working in product research and development at a company that has a culture of curiosity and innovation.

community harvest project: FLOATING ARM trebuchet

In the fall of 2019 I designed a floating arm trebuchet rated to throw a pumpkin with a 1000lb counterweight for a fundraiser event. With the help of my coworkers we assembled the trebuchet over 5 days of building and successfully fired some pumpkins!

Work Samples

Virtudent dental kit 3d printed parts

During my first co-op with Virtudent (Jan-June 2018), I was assigned to design and print a variety of parts to improve their portable dental kit.

Generate Adapt Phone Case

In the spring of 2019 I joined Generate, the product development club at Northeastern University. Over the course of the semester I worked on a team of 6 engineers to design a phone case with a modular, wireless charging battery pack.

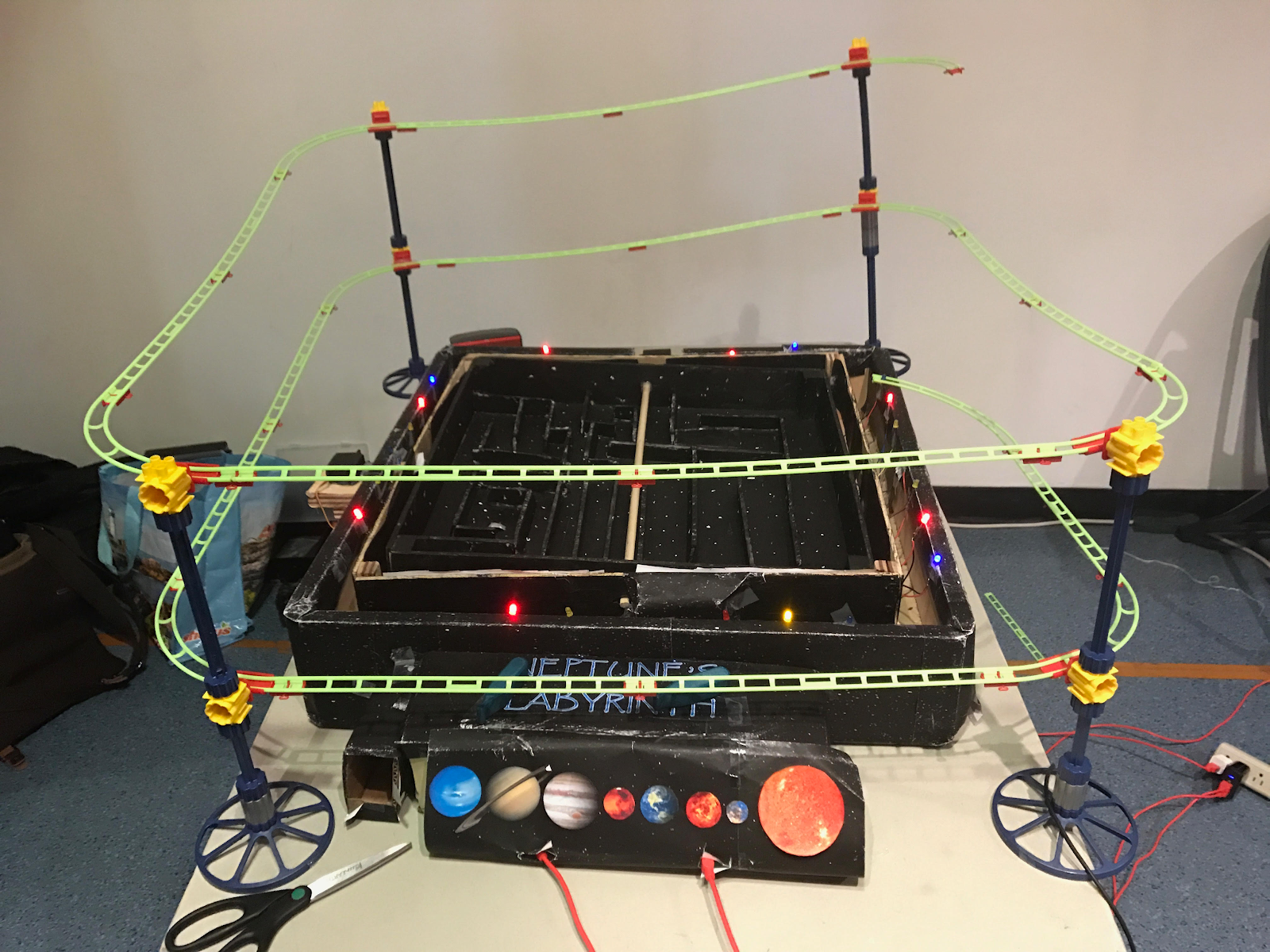

Boston Children’s Museum Labyrinth exhibit

During my cornerstone course in 2017 we were given a project to design and build an interactive exhibit for the Boston Children’s Museum. My group created an electronic version of a classic labyrinth game, where a user has to navigate a marble through a maze. Our version was created out of wood and 3D printed parts, and programmed with Arduino.